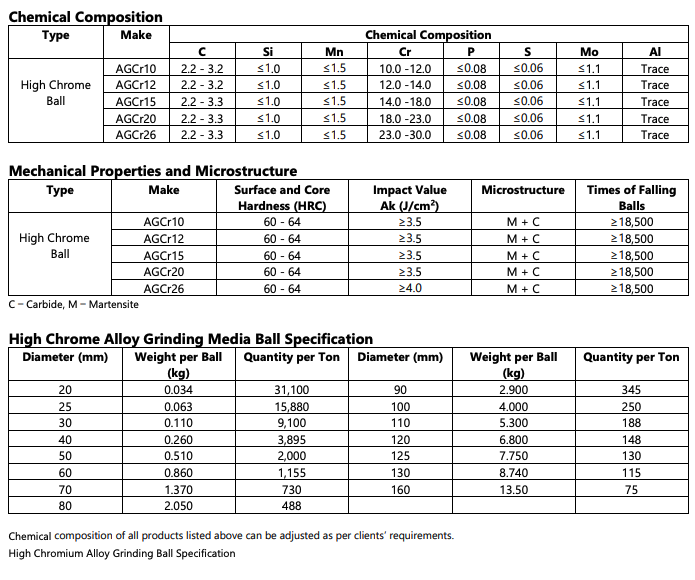

TECHNICAL SPECIFICATION – High Chromium Alloy

DESCRIPTION

High chromium alloy cast ball is widely used in cement building materials, metal mines, coal pulp thermal power,

chemical engineering, ceramic coatings, light industry paper, magnetic materials and other industries for powder

system preparation and ultra-fine processing.

The product hardness is high, has low wear, exhibits high toughness, and has minimal crushing. This product whilst

in use improves the surface hardness of the sphere with the wear resistance being enhanced. This allows improved

production capacity within the mill, with increased concentrate recovery rate.

CHARACTERISTICS

The three-way high chromium steel ball has high wear-resistant and is more than 2 times that of ordinary lowchromium ball and forged steel ball. The high-chromium ball wear performance implies wear consumption is low, grinding efficiency is high, grade stability is good, thereby increasing the fineness of mineral powder, improves the yield over time, but also to ensures good quality of the output ore powder.

USE

Suitable for large, medium, and small ball mill production process.